DT Series FGD Pump

Short Description:

Product Description Based on the successful design experience in manufacturing ZJ series slurry pumps and absorbed home and abroad advanced technology, we designs and manufactures DT and LT type pump,...

Product Description

Based on the successful design experience in manufacturing ZJ series slurry pumps and absorbed home and abroad advanced technology, we designs and manufactures DT and LT type pump, a special FGD engineering pump.

The max flow range can be up to 12000m3/h, the head is generally less than 100m. This type pump apply to all the desulfurization system, which can be used as a slurry circulating pump in large absorption tower and limestone slurry pump, gypsum slurry discharge pump, recycling pump, sump pump and so on.

Structure Form

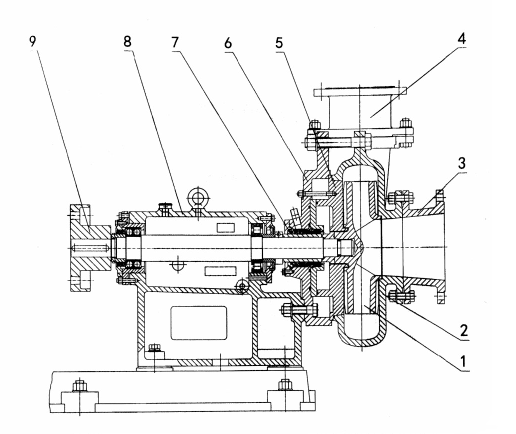

Series of DT FGD pump is a horizontal, single casing, single stage, single suction, pedestal or suspension structure pump.

| 1 | Impeller | 5 | Frame plate liner insert | 9 | Coupling |

| 2 | Volute liner | 6 | Stuffing box | 10 | Base plate |

| 3 | Suction short pipe | 7 | Mechanical seal | ||

| 4 | Discharge short pipe | 8 | Frame |

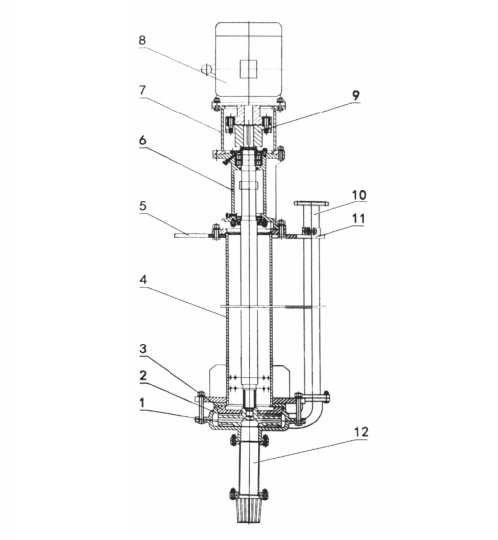

Series of LT FGD pump is vertical, single casing pump. Adding suction pipe can meet the requirements of various operating conditions.

| 1 | Impeller | 5 | Left support plate | 9 | Coupling |

| 2 | Volute liner | 6 | Bearing housing | 10 | Discharge pipe |

| 3 | Frame plate liner insert | 7 | Motor support | 11 | Right support plate |

| 4 | Column | 8 | Motor | 12 | Suction pipe |

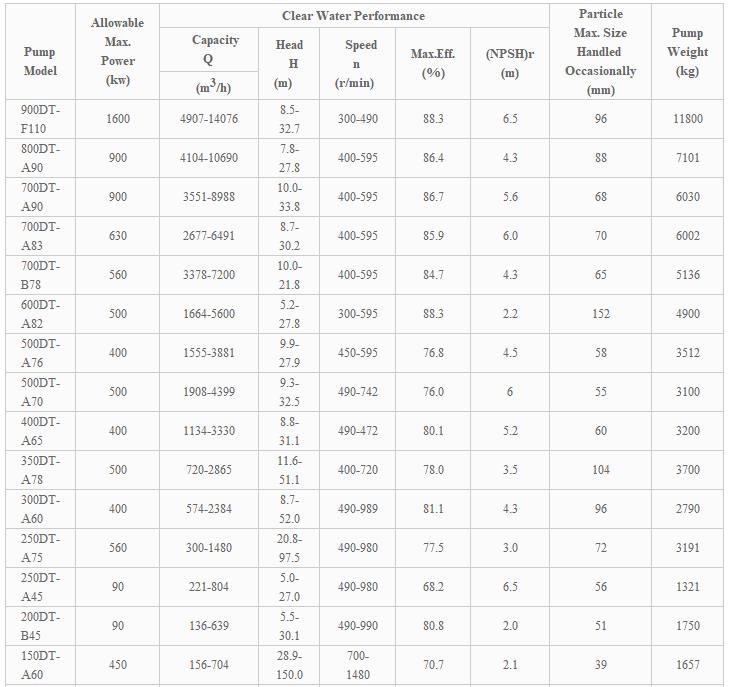

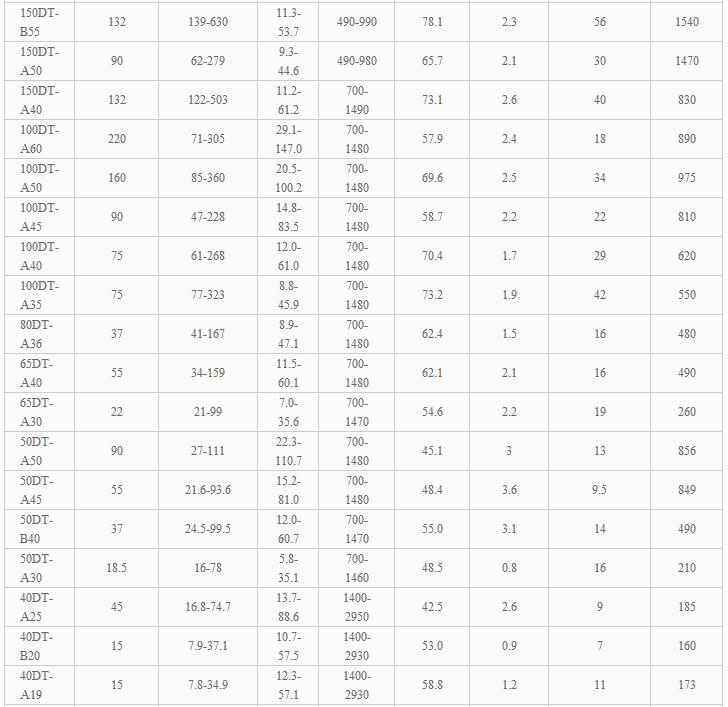

Technical Parameters (DT)

Applicable Condition

PH value: 2.5~13

Chloride ion concentration: ≤60000ppm

Concentration weight: ≤60%

Medium temperature: ≤120℃

Performance and material characteristics

- High efficiency, long service life and reliable operation.

- The wet parts are made of low carbon stainless steel material.

- Low carbon stainless steel mainly consisting of ferritic has excellent resistance to chloride stress corrosion cracking and higher mechanical strength.

- Less hydraulic friction, the efficiency is higher than the same parameters of the metal pump about 3%.

- Metal pump is easy to control the geometric dimension and high volume efficiency. The pump parts is with high surface and small clearance. The overall efficiency of 5% higher than non-metal pump.

- The wet parts has long-service life and long-term shear wear ability. Shear sliding wear ability of metal protective plate is stronger than that of the common non-metallic materials.

- Dynamic abrasion resistance is 0.008-0.08mm every year, with high tensile strength. The pump performance can be maintained constant in the long-term abrasion conditions

Seal Type

All seal type adopt mechanical seal, divided into a water and anhydrous type.

Water type

Double face mechanical seal with double sets of friction pairs, reliable operation, can achieve the effect of liquid leakage.

Anhydrous type

The self washing mechanical seal with no water medium has the advantages of unique structure, high operation reliability and good water saving effect.