SL Metal Light Duty Slurry Pump

Short Description:

Introduction TypeS L(R) pumps are cantilevered, horizontal, centrifugal slurry pumps, which are also called light duty slurry pump. They are suitable for delivering low abrasive low density slurry for...

Introduction

TypeS L(R) pumps are cantilevered, horizontal, centrifugal slurry pumps, which are also called light duty slurry pump. They are suitable for delivering low abrasive low density slurry for metallurgical, mining, coal and building material departments. The shaft seal can adopt gland seal, expeller seal or mechanical seal.

TypeS L(R) pumps operate in high speed with small volumes and light weight to save floor area. It is mainly used to transport the slurry which contains fine particle size and weight concentration not more than 30%. The liner and impeller of this pump can be changeable ,eight with anti-abrasive metal or rubber material.

Advantages

1. Discharge branch can be positioned at intervals of 45 degree.

2. Good replaceability of components with original pump.

3. Wear-resistant metal and long service life time.

4. With greater axial and radial load rating capacity,

5. Discharge direction can be installed at intervals of 45 degrees as request and oriented to any eight positions to suit applications.

6. Suit different working condition.

7. Wide application, high efficiency and easy to maintain.

8. Wide options for impeller.

9. Bearing assembly use grease lubrication.

Technical Parameters

| Pump Model | Allowable Max. Power(kw) |

Clear Water Performance | ||||||

| Capacity Q | Head H (m) |

Speed n (r/min) |

Max.Eff. (%) |

NPSH (m) |

Impeller. Dia. (mm) | |||

| m3/h | l/s | |||||||

| 20SL-YA | 7.5 | 2.34-10.8 | 0.65-3 | 6-37 | 1400-3000 | 40 | 2.5-3 | 152.4 |

| 50SL-YB | 15 | 11.5-76 | 3.2-21.1 | 8.5-46 | 1400-2800 | 62 | 2.5-5.5 | 190 |

| 75SL-YC | 30 | 18-151 | 5-42 | 4-46.4 | 900-2400 | 57 | 3-6 | 229 |

| 100SL-YD | 60 | 46.8-324 | 13-90 | 7-48.3 | 800-1800 | 64 | 2-6 | 305 |

| 150SL-YE | 120 | 115-568.8 | 32-158 | 10.5-51.8 | 800-1500 | 60 | 2.5-6 | 381 |

| 200SL-YE | 120 | 234-910 | 65-235 | 9.5-40 | 600-1100 | 64 | 3-6 | 457 |

| 250SL-YE | 120 | 396-1425 | 110-396 | 8–30 | 500-800 | 77 | 2-10 | 550 |

| 300SL-YS | 560 | 468-2538 | 130-708 | 8-60 | 400-950 | 79 | 2-10 | 653 |

| 350SL-YS | 560 | 650-2800 | 180-780 | 10-59 | 400-840 | 81 | 3-10 | 736 |

| 400SL-YST | 560 | 756-3312 | 210-920 | 7-37.5 | 300-600 | 85 | 2-8 | 825 |

| 450SL-YST | 560 | 1080-4356 | 300-1210 | 9-40 | 300-550 | 87 | 3-10 | 933 |

| 550SL-YTU | 1200 | 1980-7920 | 560-2200 | 10-50 | 250-475 | 86 | 4-10 | 1213 |

| 650SL-YTU | 1200 | 2520-9108 | 700-2530 | 10-55 | 200-350 | 86 | 2-8 | 1425 |

| 50SL-YBR | 15 | 9-61 | 2.5-17 | 3-32.4 | 1200-2600 | 48 | 2.75-4.5 | 190 |

| 75SL-YCR | 30 | 28.8-154.8 | 8-43 | 9-43 | 1100-2300 | 60 | 3-5 | 229 |

| 100SL-YDR | 60 | 54-288 | 15-80 | 12-38 | 800-1600 | 65 | 2.5-5.5 | 305 |

| 150SL-YER | 120 | 72-576 | 20-160 | 4-38 | 800-1300 | 65 | 2.5-5.5 | 381 |

| 250SL-YER | 120 | 396-1425 | 110-396 | 8-30 | 500-800 | 77 | 2-10 | 550 |

| 300SL-YSR | 560 | 432-1900 | 120-528 | 7-41 | 400-800 | 81 | 3-8 | 653 |

| 350SL-YSR | 560 | 720-2844 | 200-790 | 10-41 | 400-700 | 86 | 3-7 | 736 |

| 400SL-YSTR | 560 | 720-3312 | 200-920 | 7-51 | 300-700 | 80 | 2-10 | 825 |

| 450SL-YSTR | 560 | 1008-4356 | 280-1210 | 9-48 | 300-600 | 80 | 2-9 | 933 |

| 550SL-YTUR | 1200 | 1980-7920 | 560-2200 | 10-50 | 250-475 | 86 | 4-10 | 1213 |

| 650SL-YTUR | 1200 | 2520-9108 | 700-2530 | 10-39 | 200-350 | 86 | 2-8 | 1425 |

| Remark: 1. Capacity range recommended: 50%Q’≤Q≤110%Q’(Q’ Appropriate to capacity at highest efficiency point). 2. NPSH: appropriate to point Q recommended at highest speed |

||||||||

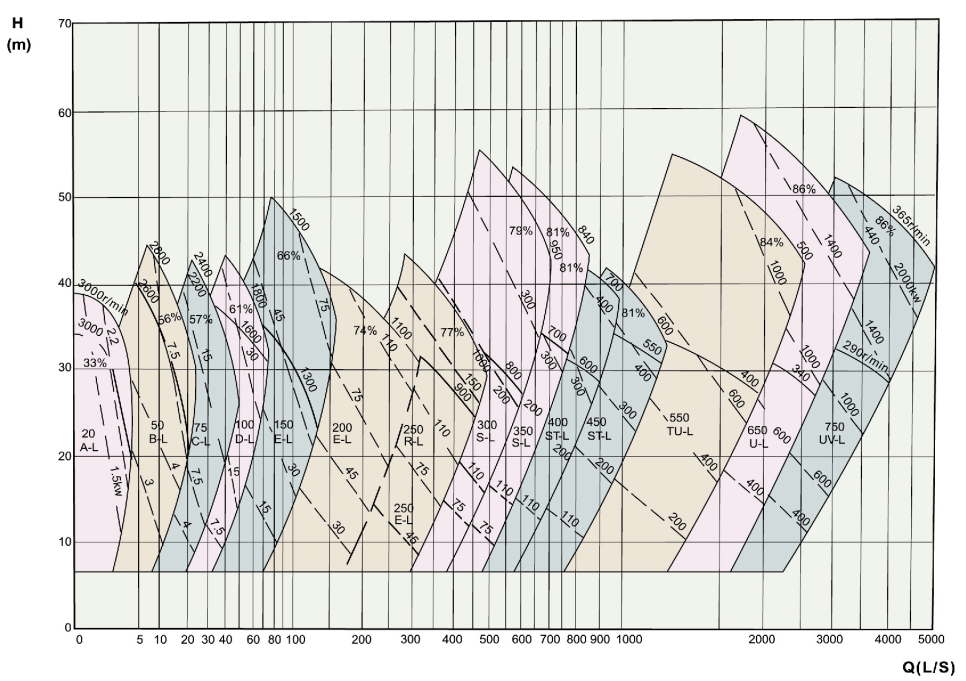

Selection Chart

Application

SL(R) series slurry pump is widely used in metallurgy, mining, mineral processing, dredging, dewatering, water treatment, coal washing, mill, cyclone feed, tailing, power, building material…etc. various industrial sites. Our pumps are called different names for different working duties: Mineral processing pump, Mill discharge slurry Pump, Booster pump, Feeding pump, Tailing pump, Transfer pump Thickner Underflow Pump, De-watering screen pump, Pressure pump, Concentrate pump…