ZGB High Performance Slurry Pump

Short Description:

Introduction In order to meet the requirements on the development of the electric power, metallurgy and coal industries, our factory has designed and developed series ZGB(P) up-to-date generation slur...

Introduction

In order to meet the requirements on the development of the electric power, metallurgy and coal industries, our factory has designed and developed series ZGB(P) up-to-date generation slurry pump with large capacity, high head, multi-stages in series to remove ash & sludge and to deliver liquid-solids mixture, based on the experience of slurry pump design and manufacture for many years, and abstracting the research results of advanced technology from home and abroad. The main technical features are as follows,

CAD modern design , super hydraulic performance, high efficiency and lower abrasive rate;

Wide passage, non-clogging and good performance of NPSH;

Expeller seal combined with packing seal and mechanical seal have be adopted to guarantee the slurry from leakage;

Reliability design ensures long MTBF (mean time between events);

The metric bearing with oil lubrication, reasonable lubrication and cooling systems ensure the bearing to be operated under the low temperature;

The materials of wet parts have the good performance of anti-wearing and anti-corrosion.

The pump can be used for seawater ash-removing to prevent it from the corrosion of seawater, salt and mist, and electrochemical corrosion;

The pump can be operated in series with multi-stage within permissible pressure.

The permissible maximum working pressure is 3.6MPa.

The series of pump has the advantages of reasonable construction, high efficiency, reliable operation and easy maintenance. It can be widely used for handling the mixture contained of abrasive and corrosive solids in electric power, metallurgy, mine, coal, constructional material and chemical industry departments, especial for removing ash and sludge in electric power station.

Product Features

1. The series ZGB(P) slurry pump is of horizontal, single-stage, single-suction, cantilever, double-casing, centrifugal slurry pump. The pump rotates in clockwise viewed from the drive end.

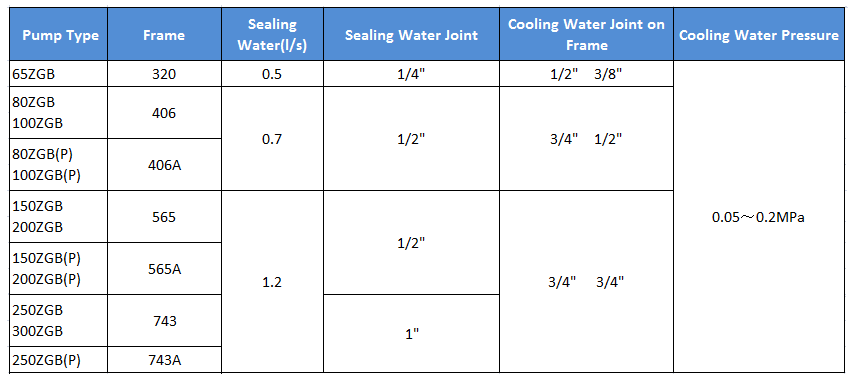

2. The wet parts of ZGB and ZGBP pump at the same outlet diameter can be interchangeable. Their outline installation dimensions are one and the same. For the drive part of the series ZGB(P) slurry pump, the horizontal split frame with oil lubrication and two sets of water cooling systems inside and outside has been adopted. If necessary, cooling water can be supplied. The prepared joint for cooling water and the pressure of the cooling water can be seen in table 1.

3. Two kinds of shaft seal—expeller seal combined with packing and mechanical seal have been used for series ZGB(P) slurry pump.

4. The mechanical seal supplied with high pressure sealing water is recommended when the slurry pump is operated in series(two stages and above two stages), and the expeller seal combined with packing is used in single-stage pump.

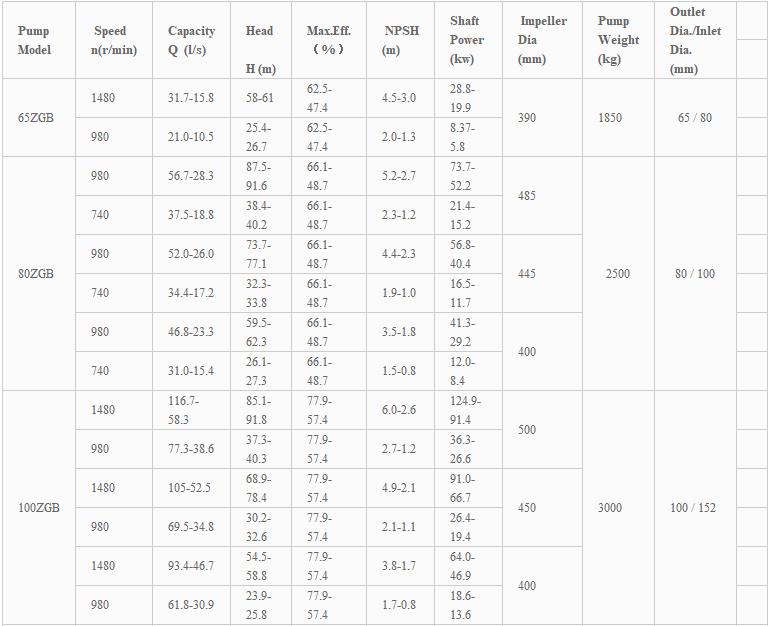

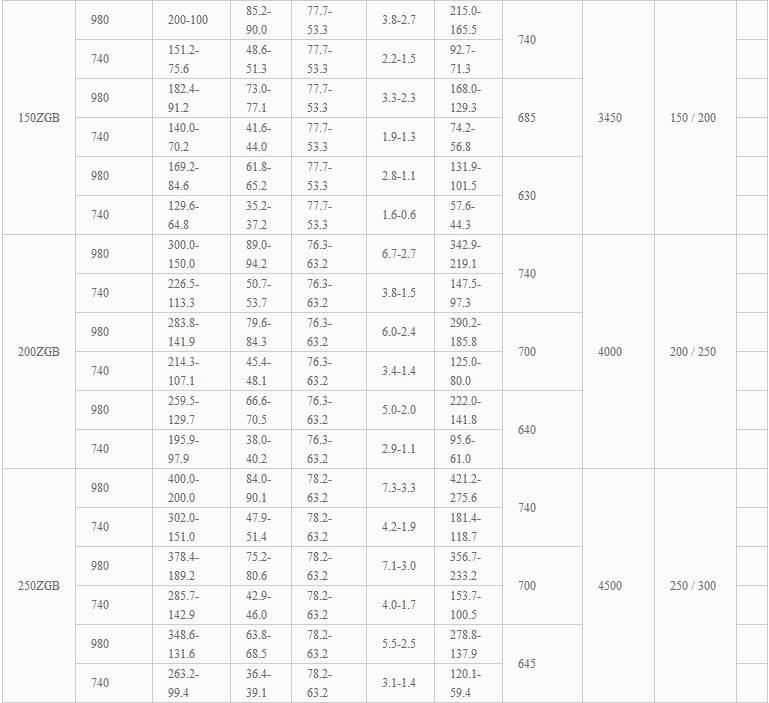

Technical Parameters

The water pressure and amount of all kinds of the shaft seal is as follows

Sealing water pressure

For single-stage pump with the expeller seal combined with packing, the water pressure of the shaft seal is 0.2-0.3MPa.

For multi-stage(two and above two stages) in series operation with the expeller seal combined with packing, the sealing water pressure should be:

The lowest sealing water pressure of n stage

Pn=  Hi+0.7Hn;Hi is i stage pump head;Hn is n stage pump head.

Hi+0.7Hn;Hi is i stage pump head;Hn is n stage pump head.

For mechanical seal, the sealing water pressure of each stage of pump is higher 0.1MPa than pump discharge pressure.

Sealing water pressure(see table 1)